Ductile Iron Body

(Series 050/051)

ABS, Coast Guard, NSF – Approvals

Description:

- Iron Body Butterfly Valve; sizes 1-1/2” – 48”

- Wafer and Lugged Body Styles Available

- Manual Valves with handle or gear operator available

- ISO 5211 mounting patterns for ease of actuation

-

ABS Type Approval, Certificate Pending

-

Coast Guard, NSF – Approvals

Literature:

Data Sheets:

Engineering Drawings:

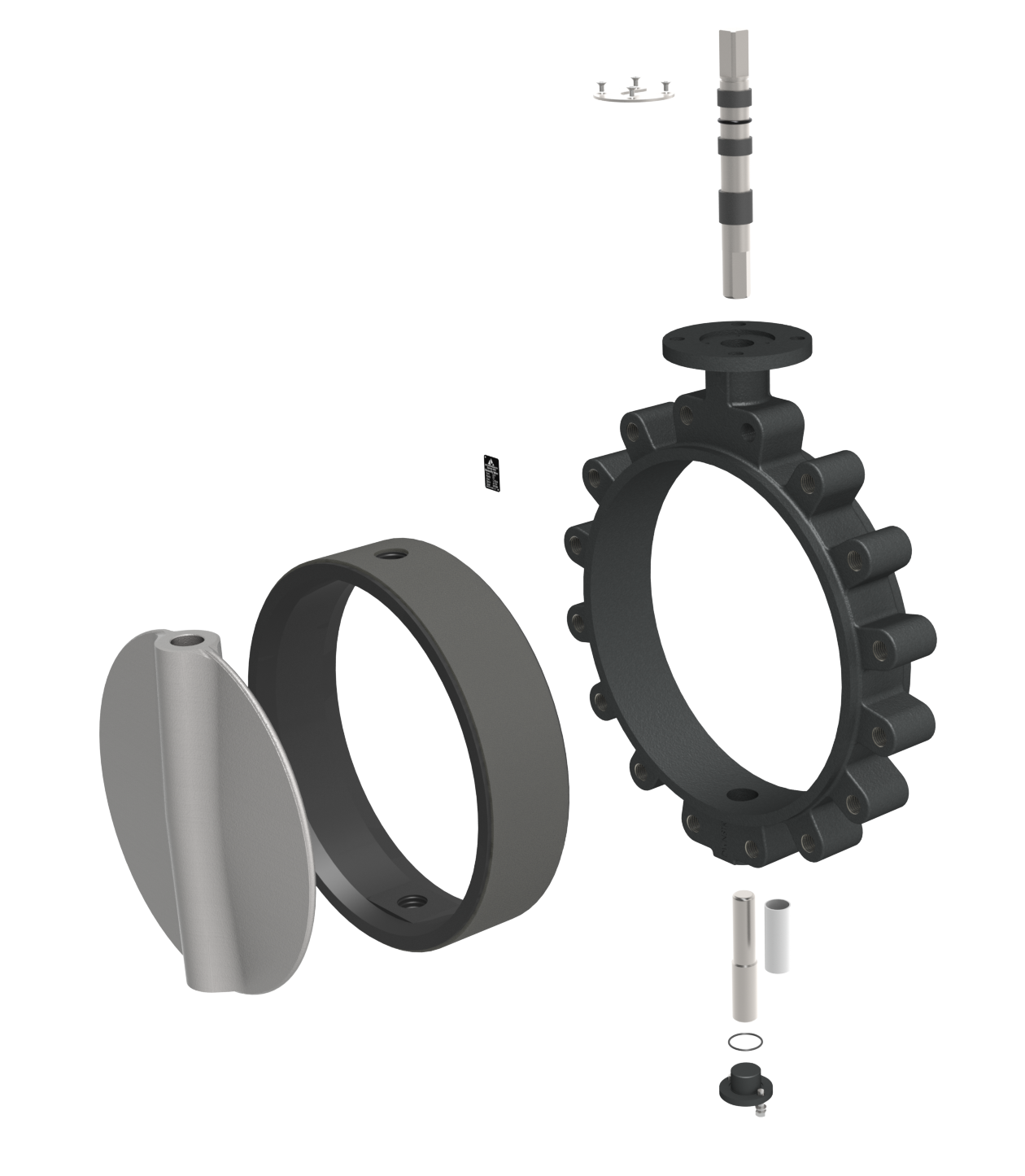

Exploded View

(1-1/2” – 12” Sizes)

(14-48” Sizes)

Disc Materials

(Details, Recommend Applications, Not Recommended For)

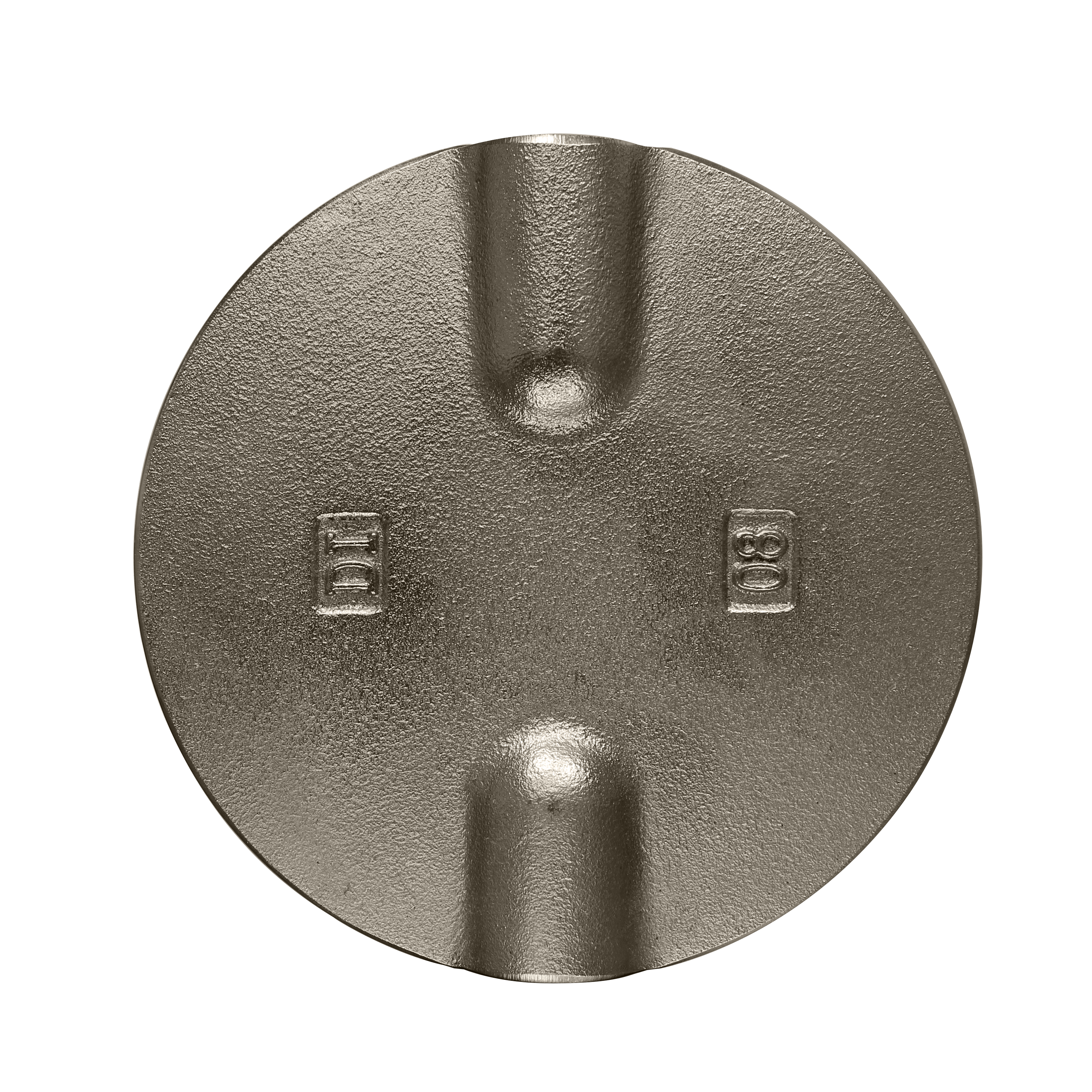

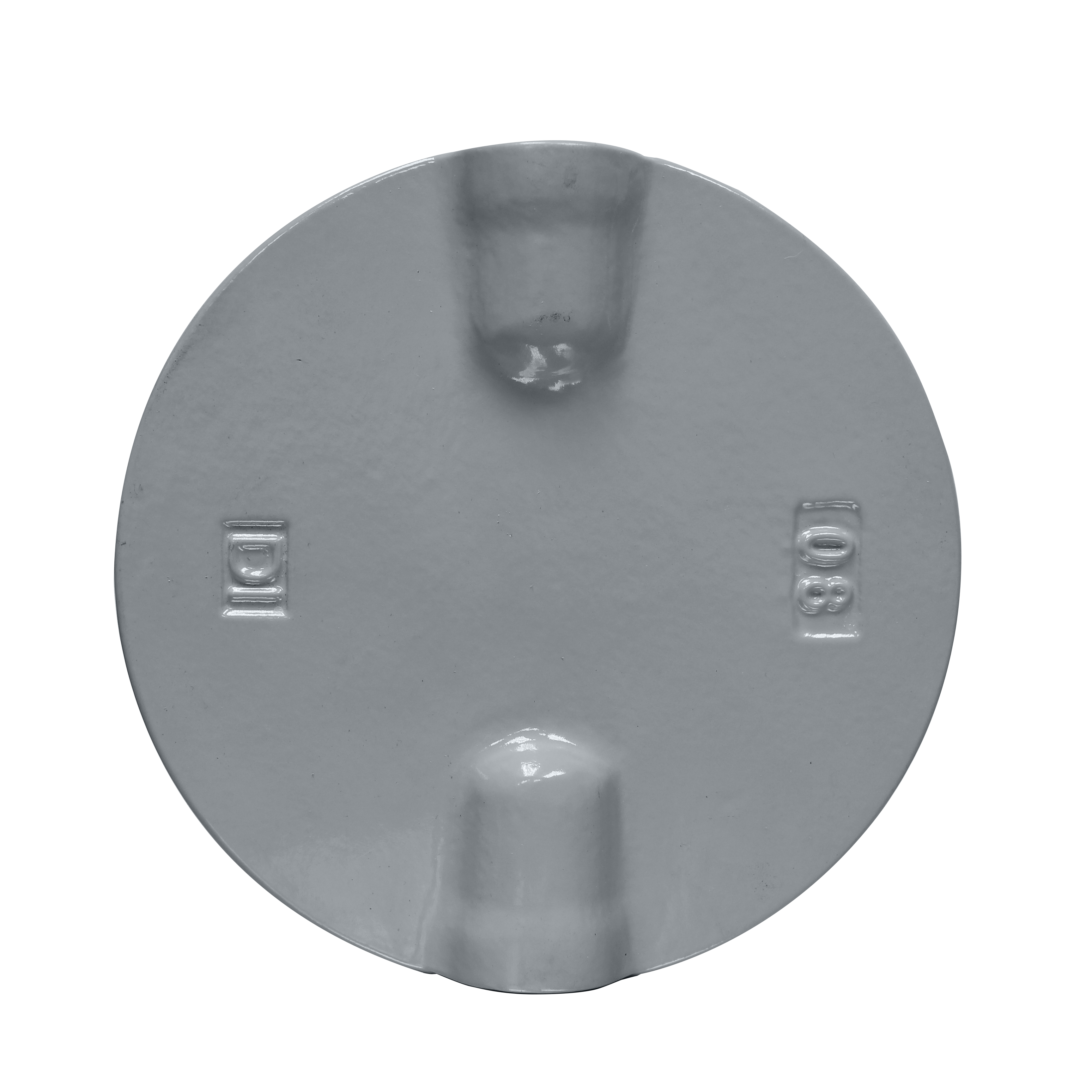

DI-NP

Nickel Plated Ductile Iron Ductile iron disc for strength, coated with Nickel Plating for corrosion resistance and increased abrasion resistance.

Recommend Applications: Air, Kerosene, Oils, Ketones, Hydrocarbons, Solvents, Detergents, Salts, Concentrated Organic Acids

Not Recommended For: Inorganic Acids, Diluted Organic Acids

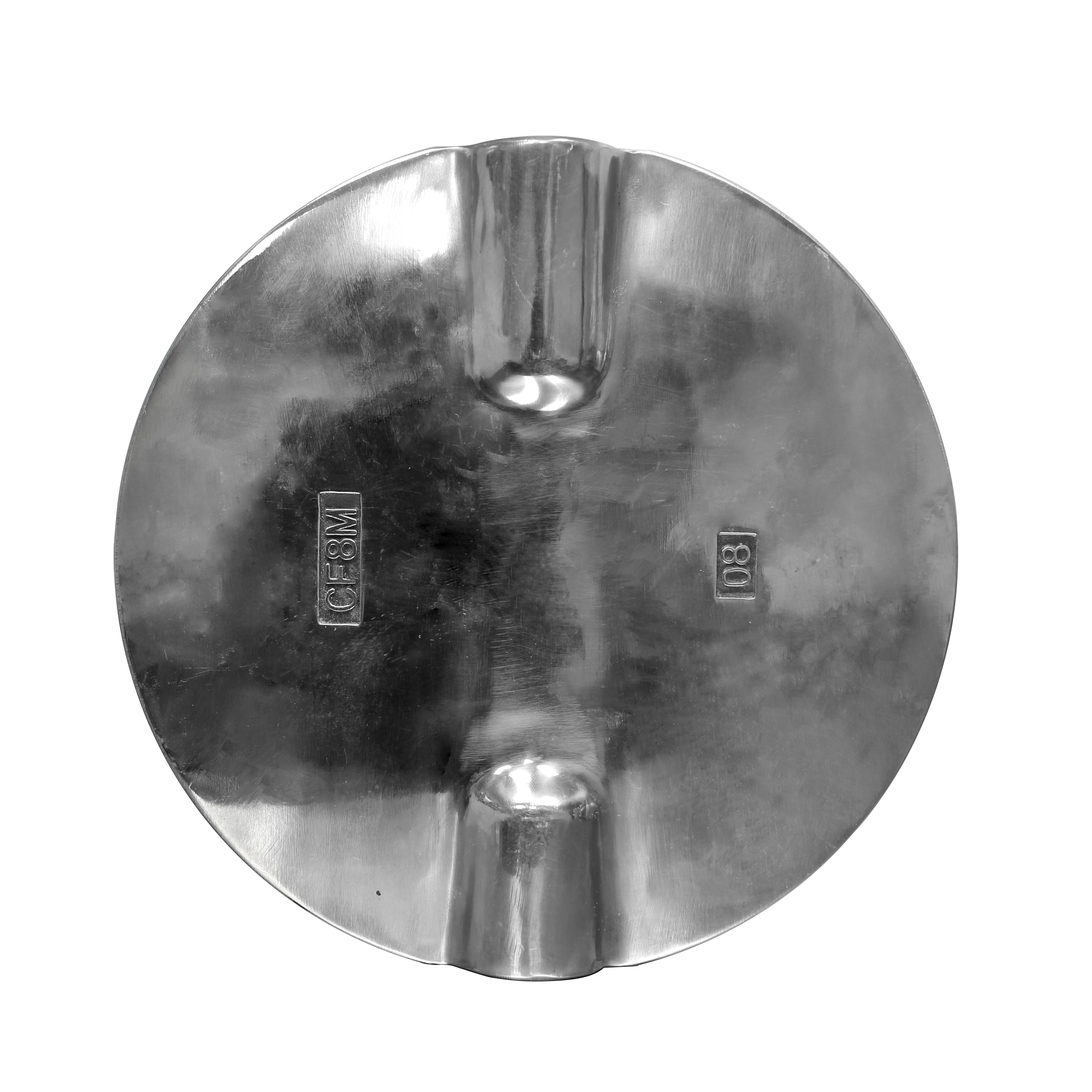

CF8M

316 Stainless Steel Stainless steel disc is inherently strong for industrial use and corrosion resistant for a wide range of chemical and environmental applications.

Recommended Applications: Acetic Acids, Air, Automotive Oils & Fuels, Beer, Freon, Gasoline, Ketones, Oils, Oxygen, Steam, Sea Water, Potable Water

Not Recommended For: Acids

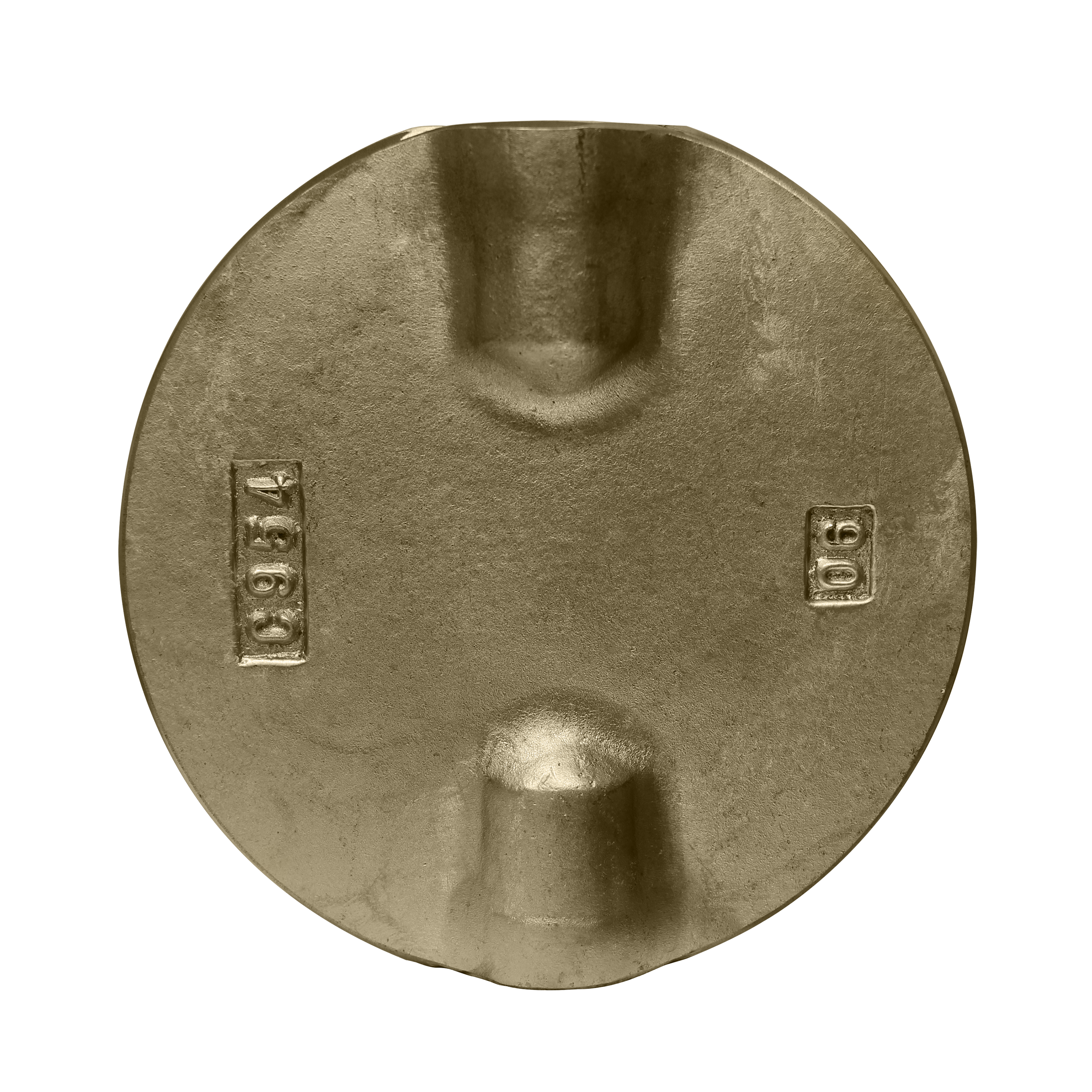

AL-BZ

Aluminum Bronze Strength similar to carbon steel, but with an aluminum oxide layer on the surface for excellent corrosion resistance.

Recommended Applications: Sea water, brine, detergents, gasoline, alcohols, esters, ketones, potable water

Not Recommended For: Acids

Polished

Polished 316 Stainless Steel All the benefits of stainless steel strength and corrosion resistance, plus a highly polished surface for sanitary applications.

Recommended Applications: Sanitary Applications, Potable Water

Not Recommended For: Acids

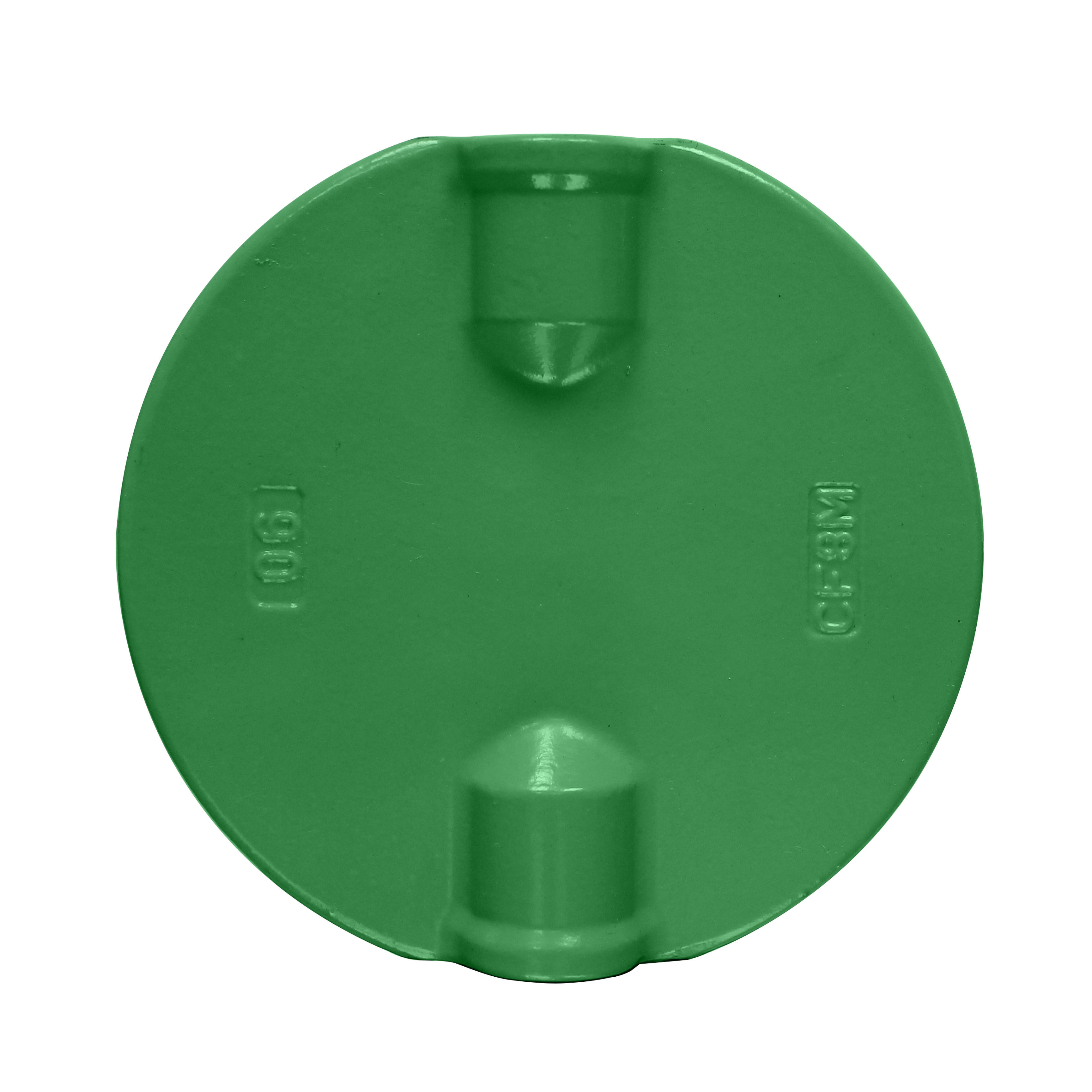

NY11

Nylon 11 Coated Ductile Iron Ductile iron disc for strength, coated with Nylon 11 for corrosion resistance and excellent abrasion resistance.

Recommended Applications: Inorganic salts, alkalis, most solvents, most organic acids, hydrocarbons, oils, kerosene, ketones, esters, detergents, sea water, abrasives

Not Recommended For: Inorganic acids, phenols, chlorinated solvents

PTFE

PTFE Coated 316 Stainless Steel

Recommended Applications: Acids, Alcohols, Solvents, Oils, Potable Water

Not Recommended For: Fluorine

Seat Material Guide

(General Applications, Temperature Range at Full Rated Pressure, Not Recommended For)